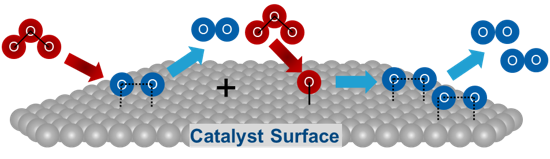

PremAir® BLD catalyst technology is designed to convert harmful ozone into oxygen at room temperatures improving indoor air quality for both commercial and residential applications.

BASF has over 40 years of experience in developing solutions for clean air for a wide range of applications. As the global leader in catalysis, BASF is continuously developing technologies to address developing air quality issues. PremAir® BLD is a customizable ozone solution to meet your specific needs.

By controlling the porosity and depth, we provide you with the ability to remove ozone to non-detectable quantities. BASF’s proprietary technology ensures excellent adhesion to prevent dusting and flake off. With minimal catalyst protection, PremAir® BLD will provide effective ozone conversion for prolonged periods of time. BASF assists its customers in modeling potential performances in specific application.

Uses for PremAir® BLD

Ozone is used in disinfection scenarios, for example in air purifiers, HVAC and disinfection cabinets, to sanitize items which may be contaminated. PremAir® BLD has been shown to be very effective in eliminating ozone concentrations up to 100ppm in short periods of time. Ozone is also a by-product for other popular air purification methods such as plasma technology and UV lights. In combination with PremAir® BLD, ozone exposure can be mitigated. When incorporated into an air purifier utilizing these technologies, PremAir® BLD contributes to a safer indoor air environment.

PremAir® BLD removes harmful ozone from indoor air making it easier to breathe. It’s ability to remove high concentrations of ozone enable other technologies to further purify the air and objects ensuring a safe environment.

Low O3 (<250ppb)

VOCs reacting with NOx and UV light can produce dangerous levels of ground level ozone (O3) causing severe asthma, emphysema and chronic bronchitis. PremAir® BLD was originally developed to remove low levels of O3 from ambient air by placing the catalyst in a HVAC system. The MnOx based catalyst is coated on aluminum honeycomb to form a easily installable filter

Medium [O3] (250ppb-5ppm)

With an increased need to remove viruses from indoor air, the air purifying industry is starting to use plasma technology to kill airborne viruses and bacteria. However, ozone is generated in the process and must be removed to ensure a safe breathing environment. Therefore, PremAir® BLD is utilized to decrease ozone below the odor threshold of 25ppb. Models were generated to determine optimal catalyst usage.

High [O3] (25-50ppm)

To ensure viruses and bacteria are not transferred from objects to people, several companies now produce chambers utilizing high concentrations of ozone to disinfect everything from toys to space suits and even PPE! To remove the ozone after the disinfection cycle, PremAir® BLD is employed to quickly remove excess ozone in the chamber guaranteeing a safe atmosphere before opening the chamber.